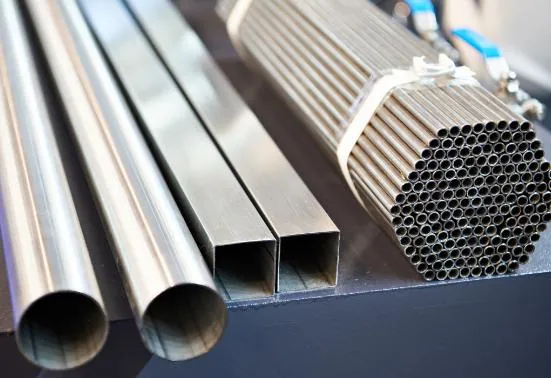

Stainless Steel Grades

Stainless steel comes in a variety of types, each with a unique composition that delivers distinct advantages. These alloys are categorized into five families, which are further divided into grades with specific properties such as toughness, magnetism, and corrosion resistance. As a global leader in stainless steel alloy distribution, Continental Steel & Tube Company offers quality products backed by unparalleled expertise. Below, you can learn more about our extensive product line, which includes specialty Duplex grades, large-diameter bars, and much more.

Types of Stainless Steel Grades and Families

Stainless steel grades are divided into five categories, based on their crystalline structure or the type of heat treatment used to develop their attributes. Two of the categories, austenitic and ferritic, are widely used, while the martensitic, duplex, and precipitation hardening categories are more specialized.

- Austenitic. The addition of nickel, nitrogen, or manganese creates austenitic stainless steel’s crystal structure. Austenitic stainless steels are more expensive than ferritic grades but offer better formability and weldability, as well as excellent toughness.

- Ferritic. Ferritic stainless steel gets its crystalline structure from iron atoms. It is more affordable than other families because it does not contain nickel. While it offers excellent resistance to chloride stress corrosion, it is less formable and weldable than austenitic stainless steel.

- Duplex. This family includes proprietary and more recently developed alloys. They often display a combination of austenitic and ferritic stainless steel properties.

- Martensitic. Martensitic stainless steels are more uncommon than other families but excel in applications that require a precision, hardened edge.

- Precipitation-hardening. Also relatively uncommon, precipitation- hardening alloys are magnetic and provide moderate to good corrosion resistance.

Questions? Speak with a Metal Specialist.

Contact Us200 Series: Austenitic Chromium-Nickel-Manganese Alloys

300 Series: Austenitic Chromium-Nickel Alloys

400 Series: Ferritic and Martensitic Chromium Alloys

600 Series: Precipitation Hardening Alloys

Duplex Stainless Steel

Additional Stainless Steel Grades

Continental Steel & Tube, Your Trusted Stainless Steel Supplier

Continental Steel & Tube Company has been a trusted source of stainless steel forms since 1985. Our clients come from demanding backgrounds, including marine, aerospace, construction, oil and gas, food processing, military, medical, and more. Our specialists can help you identify the best type of stainless steel for your project and quickly access the forms you need.

As part of our commitment to quality, we are ISO 9001:2015 certified and AS9120B:201 registered. Contact our metal experts with any questions or request a quote today to get started.