Alloy 400 and Alloy 405 are nickel-copper alloys used in demanding industries. Also known as Monel® 400 and Monel® 405, these alloys are prized for their impressive corrosion resistance, high strength, and toughness in extreme or varying temperatures. We’ll explore the unique properties, applications, and benefits of Nickel Alloy 400 and 405 forms in round bars and hexagonal (hex) bars.

Understanding Alloy 400/405

Alloy 400 (Monel® 400) combines nickel and copper with smaller amounts of iron, manganese, and other elements. These alloys offer excellent resistance in corrosive environments, including seawater, hydrofluoric acid, sulfuric acid, and alkalies. Alloy 400 boasts high strength and toughness, even at sub-zero temperatures. This makes it a popular material in demanding industrial applications.

Alloy 405 (Monel® 405) is the free-machining grade of Alloy 400. This alloy has a similar chemical composition to Alloy 400 but with a higher sulfur content for improved machinability. Alloy 405 is ideal for manufacturing components that require precise and complex machining.

Applications and Benefits: Nickel Round Bars in Alloy 400 & 405

Applications

Nickel round bars in 400 and 405 grades are widely used materials. Key applications include:

- Aerospace. Used in various aerospace components like fasteners and structural components for improved strength and corrosion resistance

- Marine Engineering. Used in the fabrication of propeller shafts, pump shafts, and other marine components that must withstand prolonged exposure to seawater

- Chemical Processing. Ideal for producing valves, pumps, and heat exchangers that can tolerate exposure to corrosive chemicals like hydrofluoric acid and sulfuric acid

- Oil and Gas Industry. Used to produce downhole tools, pump shafts, and other components exposed to corrosion and high pressures

Benefits

Some benefits are unique to specific grades. For instance, the improved machinability of Alloy 405 makes it easier to produce intricate components without compromising the material’s overall properties. Other advantages come with using either grade, such as:

- Corrosion Resistance. Both Alloy 400 round bars and Alloy 405 round bars exhibit excellent resistance to a wide range of corrosive environments, making them suitable for harsh conditions.

- Strength and Toughness. These alloys maintain their strength and toughness across a broad temperature range, from cryogenic to high temperatures.

- Versatility. Round bars can be machined, forged, and fabricated into various components, allowing for customization in different industries.

Applications and Benefits: Hexagonal Bars in Alloy 400 & 405

Applications

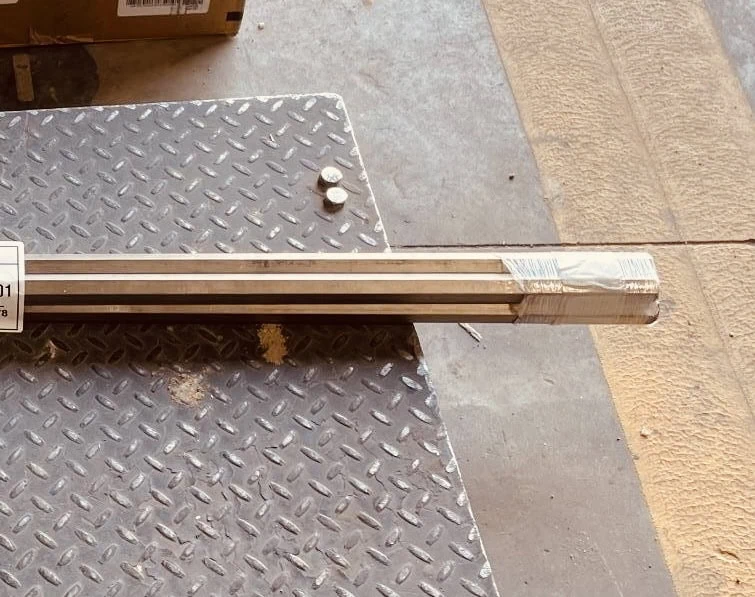

Hexagonal bars in Alloy 400 and 405 have a unique cross-sectional shape used in specific applications such as:

- Fasteners. Often used to produce nuts, bolts, and other fasteners that require both corrosion resistance and strength, particularly in marine and chemical environments

- Electrical Applications. Suitable for producing components used in electrical and electronic systems, due to its non-magnetic properties and resistance to corrosion

- Machined Components (Alloy 405). Used to create parts with complex geometries, such as valve components and fittings in industries where precise machining is essential

- Oil and Gas. Used to manufacture downhole components and drilling tools that must resist corrosive fluids and withstand high mechanical stress

Benefits

Hexagonal bars in alloy forms offer a range of benefits, including:

- Corrosion Resistance. Like round bars, Alloy 400 hex bars and Alloy 405 hex bars provide impressive corrosion resistance to extend the life of components.

- Efficient Machining. Alloy 400 and 405 hexagonal bars provide a convenient shape for machining into fasteners and other components. This helps reduce material waste and machining time.

- Strength and Durability. Alloy hex bars maintain high strength and toughness for reliable performance in demanding applications.

Continental Steel: Your Trusted Supplier for Alloy 400/405 Round Bars & Hex Bars

Alloy 400 and 405 round bars and hexagonal bars are essential in industries that demand exceptional corrosion resistance, strength, and machinability. These alloys provide reliable performance in some of the most challenging environments, from chemical processing to aerospace and marine engineering.

Continental Steel & Tube Company offers a large selection of nickel-based materials. We can supply round bars and hexagonal bars in Alloy 400 and 405 with sizes ranging from 1/8″ to 9”. As opportunities and uses for nickel-copper alloys continue to expand, Continental Steel will be ready with the materials you need.

In Alloy 400 grade, Continental Steel also supplies Plate, Sheet, Pipe, Tube and other forms that you can find listed in our catalog.

Contact us to learn more about our nickel alloy products or request a quote to get started on your order.