Featured Products

News

View All Articles

About Us

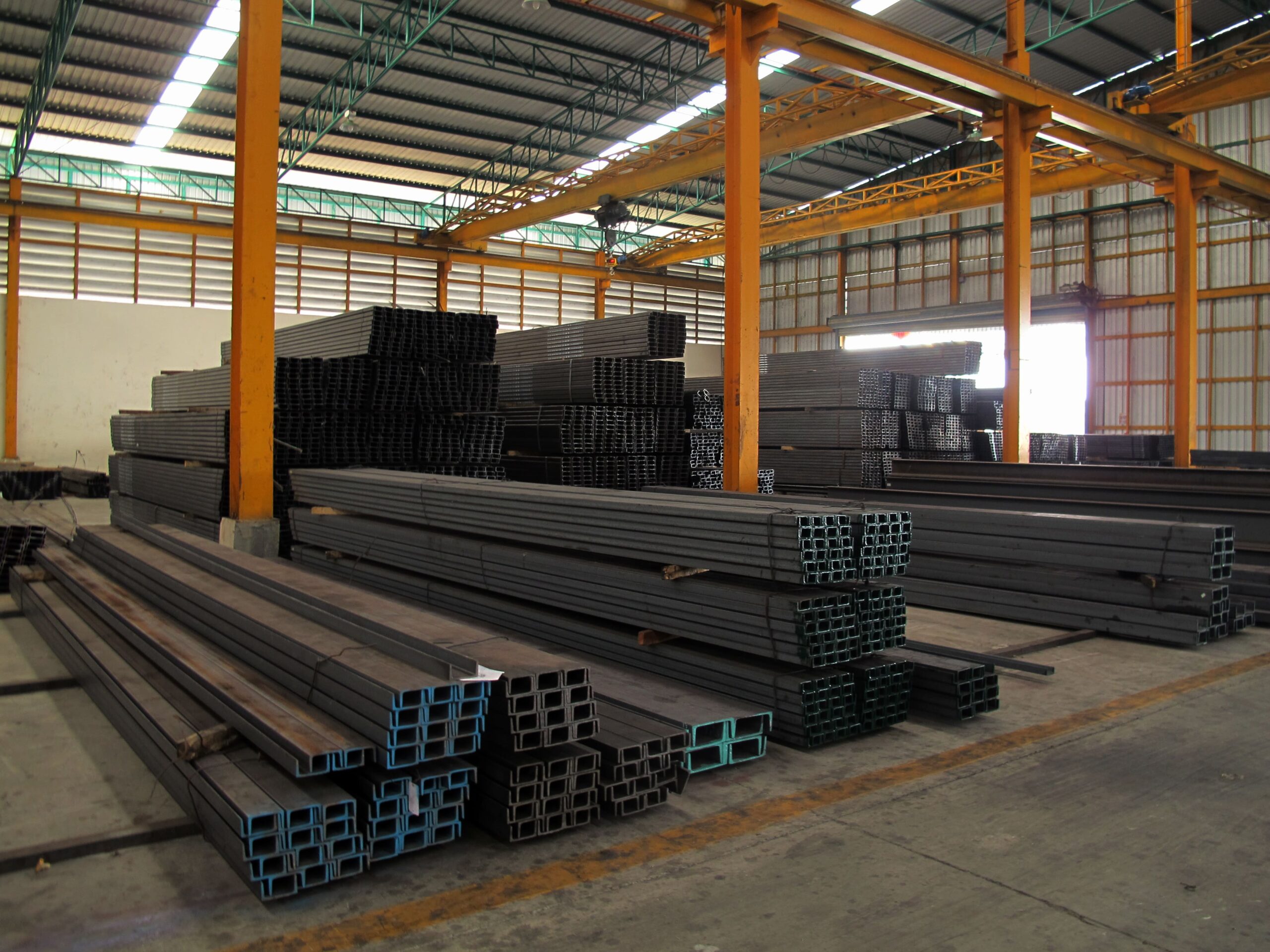

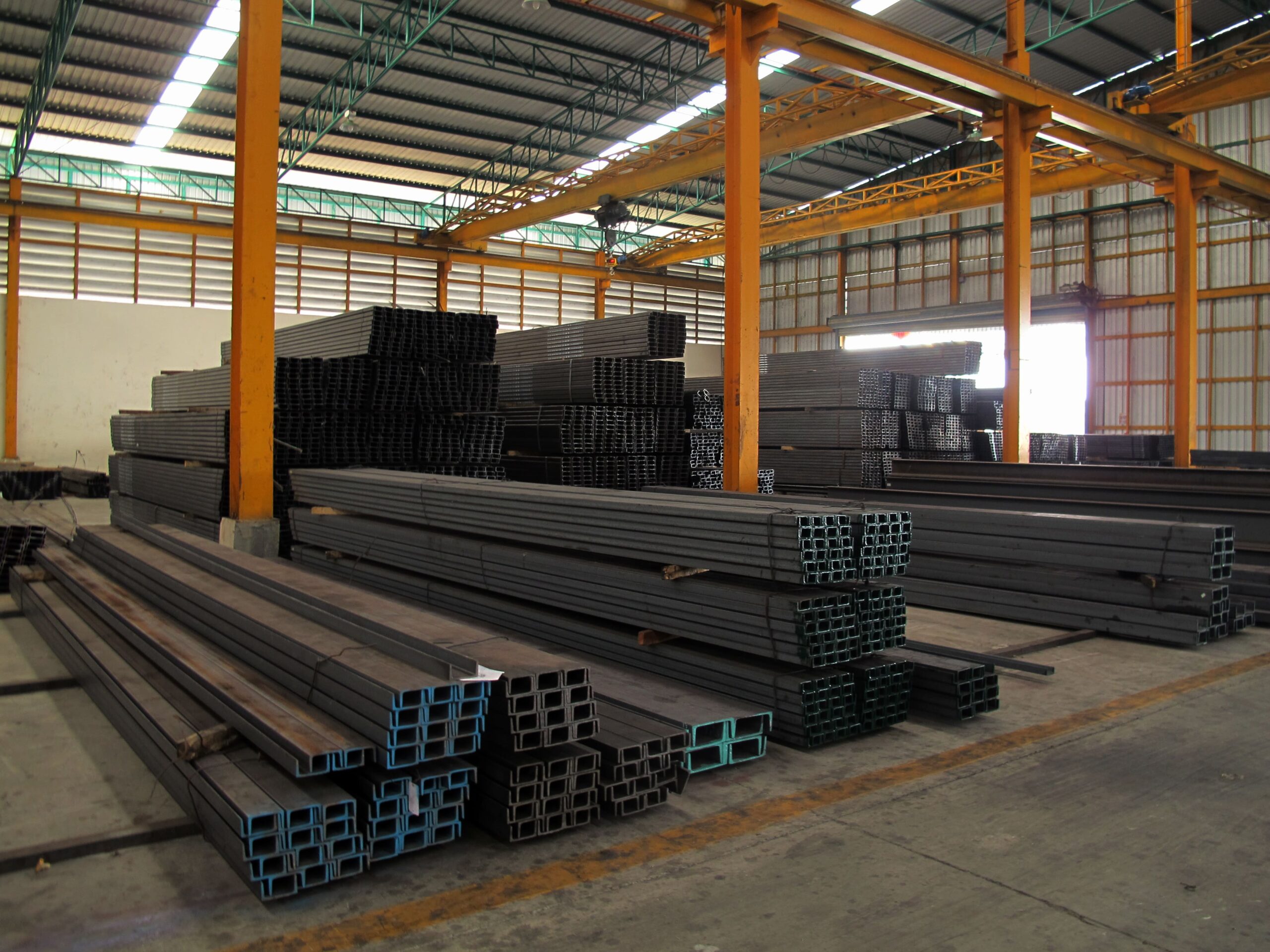

Continental Steel & Tube Company is a Titanium, Stainless Steel, Nickel, Steel, Aluminum, Brass and Bronze Value Added Volume Metals Supplier & Distributor.

Learn More About Us

Continental Steel & Tube Company is a Titanium, Stainless Steel, Nickel, Steel, Aluminum, Brass and Bronze Value Added Volume Metals Supplier & Distributor.

Learn More About Us