The aerospace industry depends on various aerospace-grade alloys to ensure aircraft parts and components meet the industry’s high standards. These components must withstand the demands of air travel, including heavy loads, high temperatures, abrasion, and corrosion. Due to their properties, copper, brass, and bronze are used extensively in the aerospace industry. They are ideal materials for manufacturing aircraft components with excellent wear and corrosion resistance, such as bearings, bushings, and wheel and brake parts.

Here, we will explore the copper, brass, and bronze alloys used in aerospace manufacturing, including the common components produced and the unique benefits these materials offer.

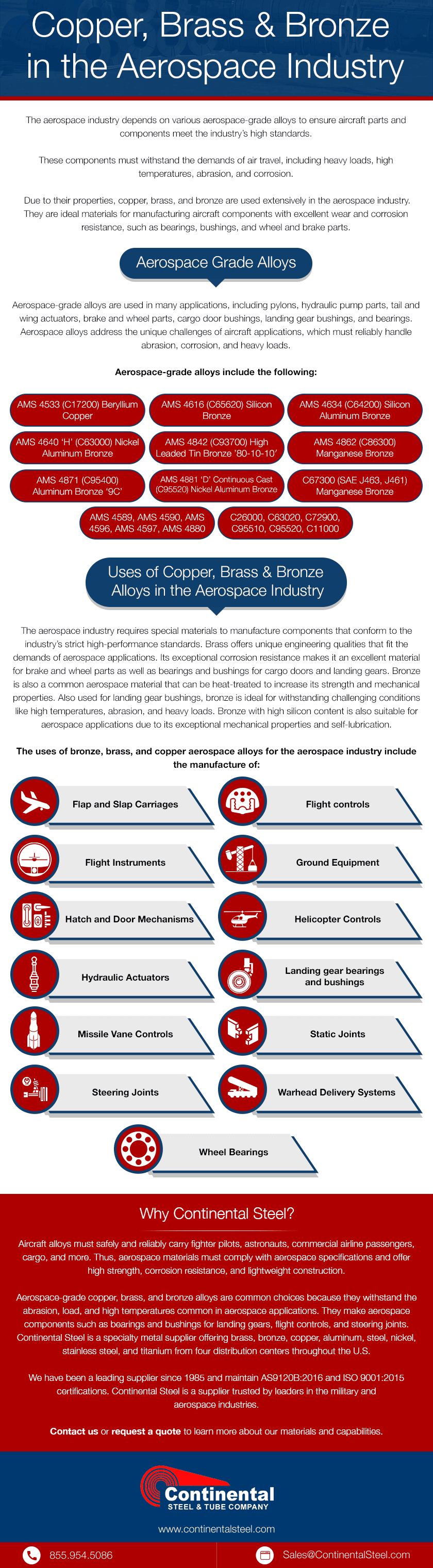

Aerospace Grade Alloys

Aerospace-grade alloys are used in many applications, including pylons, hydraulic pump parts, tail and wing actuators, brake and wheel parts, cargo door bushings, landing gear bushings, and bearings. Aerospace alloys address the unique challenges of aircraft applications, which must reliably handle abrasion, corrosion, and heavy loads. Aerospace-grade alloys include the following:

- AMS 4533 (C17200) Beryllium Copper

- AMS 4616 (C65620) Silicon Bronze

- AMS 4634 (C64200) Silicon Aluminum Bronze

- AMS 4640 ‘H’ (C63000) Nickel Aluminum Bronze

- AMS 4842 (C93700) High Leaded Tin Bronze ’80-10-10′

- AMS 4862 (C86300) Manganese Bronze

- AMS 4871 (C95400) Aluminum Bronze ‘9C’

- AMS 4881 ‘D’ Continuous Cast (C95520) Nickel Aluminum Bronze

- C67300 (SAE J463, J461) Manganese Bronze

- AMS 4589, AMS 4590, AMS 4596, AMS 4597, AMS 4880

- C26000, C63020, C72900, C95510, C95520, C11000

Uses of Copper, Brass & Bronze Alloys in the Aerospace Industry

The aerospace industry requires special materials to manufacture components that conform to the industry’s strict high-performance standards. Brass offers unique engineering qualities that fit the demands of aerospace applications. Its exceptional corrosion resistance makes it an excellent material for brake and wheel parts as well as bearings and bushings for cargo doors and landing gears.

Bronze is also a common aerospace material that can be heat-treated to increase its strength and mechanical properties. Also used for landing gear bushings, bronze is ideal for withstanding challenging conditions like high temperatures, abrasion, and heavy loads. Bronze with high silicon content is also suitable for aerospace applications due to its exceptional mechanical properties and self-lubrication.

The uses of bronze, brass, and copper aerospace alloys for the aerospace industry include the manufacture of:

- Flap and slap carriages

- Flight controls

- Flight instruments

- Ground equipment

- Hatch and door mechanisms

- Helicopter controls

- Hydraulic actuators

- Landing gear bearings and bushings

- Missile vane controls

- Static joints

- Steering joints

- Warhead delivery systems

- Wheel bearings

Why Continental Steel?

Aircraft alloys must safely and reliably carry fighter pilots, astronauts, commercial airline passengers, cargo, and more. Thus, aerospace materials must comply with aerospace specifications and offer high strength, corrosion resistance, and lightweight construction. Aerospace-grade copper, brass, and bronze alloys are common choices because they withstand the abrasion, load, and high temperatures common in aerospace applications. They make aerospace components such as bearings and bushings for landing gears, flight controls, and steering joints.

Continental Steel is a specialty metal supplier offering brass, bronze, copper, aluminum, steel, nickel, stainless steel, and titanium from four distribution centers throughout the U.S. We have been a leading supplier since 1985 and maintain AS9120B:2016 and ISO 9001:2015 certifications. Continental Steel is a supplier trusted by leaders in the military and aerospace industries. Contact us or request a quote to learn more about our materials and capabilities.