Titanium Grades

Titanium is a lightweight, strong metal that is available in several grades and compositions, each with different properties. It is categorized into commercially pure (CP) and alloy titanium, and then further divided into grades based on specific properties, such as corrosion resistance, formability, and toughness.

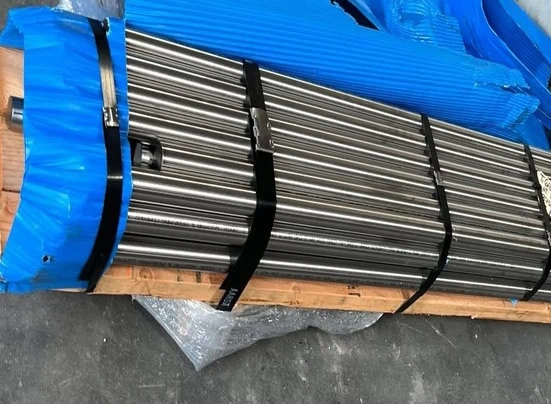

This page highlights Continental Steel & Tube Company’s comprehensive selection of titanium materials. Unless otherwise noted, all grades are available in these forms: bar (round, hex, flat), pipe, tube, plate, sheet, strip, coil, forgings, fittings and wire.

Types of Titanium Grades and Families

The two primary types of titanium are commercially pure (CP) and alloy. There are several grades of each type, and they have properties that make them suitable for various applications.

- Commercially Pure (CP) Titanium Alloys. In CP titanium grades one through four, the grade number goes up incrementally as strength increases and ductility decreases. At room temperature, these metals have a hexagonal close-packed (HCP) alpha phase, which provides a stable structure. The different grades of CP titanium are categorized by the various proportions of interstitial elements, such as nitrogen, carbon, iron, and oxygen, which can impact the ductility and strength of the alloy.

- Titanium Alloys. Titanium alloys have either an alpha or a beta crystal structure. The alpha phase has a HCP structure, and the beta phase has a body-centered cubic (BCC) structure. The ratio of the phases is influenced by the alloying elements, which significantly impact the mechanical properties. Alloys fall into four categories:

- Alpha (⍺) Alloys: Alloyed with oxygen, and trace amounts of iron and carbon.

- Near-Alpha Alloys: High-temperature alloy with high strength of alpha and beta alloys and creep behavior of alpha alloys; suitable for operating conditions up to 550 ºC.

- Beta (β) Alloys: Easier to work with in cold environments compared to other alpha-beta alloys.

- Near-Beta Alloys: Better corrosion resistance than CP titanium grades; can be heat-treated to high strengths.

Questions? Speak with a Metal Specialist.

Contact UsCP Titanium: Commercially Pure Titanium Alloy

Titanium-Based Alloys

Continental Steel & Tube, Your Trusted Titanium Supplier

Since 1985, Continental Steel & Tube Company has supplied customers with high-quality titanium metal grades as well as steel, aluminum, nickel, copper, brass, bronze, and hard-to-find metals. Our materials are available in various forms and sizes, including but not limited to pipe, tube, bar, plate, and sheet.

We are ISO 9001:2015 certified and AS9120B:2016 registered, and provide the highest level of quality and excellence in all of our services. Contact our metal experts with any questions or request a quote today to get started.