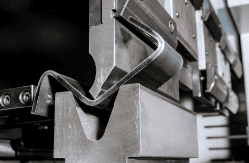

Bar Conversion – Specialty Sizes

We offer bar conversion services to transform larger round bars into flat, square, or hexagonal bars. This process involves using a lathe or other specialized equipment to cut and shape the round stock into a square or hexagonal cross-section. This can be done using turning tools that gradually remove material until the intended shape is achieved.

The conversion process ensures that the new bar maintains precise dimensions and tolerances as specified. This is particularly important for applications requiring an accurate fit for functionality.

Converting round bars into square or hexagonal bars is useful in industries where specific geometric shapes are required for components. Common applications include:

- Custom Parts

- Fittings

- Structural Elements

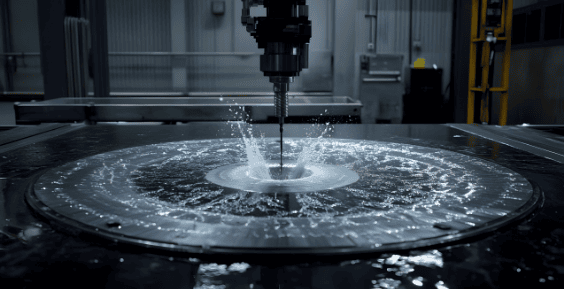

Gun Drilling

Continental Steel can provide gun drilling services to meet your project requirements. This precise machining process is used to create deep, straight, and accurate holes in metal workpieces. It is commonly employed in applications requiring a high level of uniformity and precision. If there is a tube size you cannot find, please ask us. We may be able to have a hollow bar produced that will work for your project.

Trepanning

With trepanning services, it is possible to make circular holes or cutouts in a material using a trepanning tool or hollow drill bit. This process is particularly useful for removing a core from a solid workpiece or producing holes with a significant diameter compared to the material’s thickness.

Chemical Milling

Chemical milling, also referred to as chem milling, is a chemical etching technique used to remove material from a metal surface to achieve a specific shape or reduce weight. Our chemical milling process involves applying a chemical etchant to the surface of a metal part, which selectively dissolves the metal in unprotected areas. Certain areas of the part are covered with a resistant material that protects those regions from being etched.

This process is commonly used in automotive and aerospace industries to produce intricate, lightweight components by removing excess material from plates or sheets. It allows for the precise control of material removal and is capable of achieving complex geometries that would be costly or difficult to achieve using conventional machining methods.

Key benefits of our chem milling services include:

- Quickly achieves a non-stock thickness without long lead times or mill production runs

- Reduced part weight without sacrificing structural integrity

- Smooth surface finishes

- Facilitates the creation of complex designs with minimal mechanical stress on the material

Continental Steel can provide milling on various metal materials, with the most common being aluminum, titanium, and stainless steel.

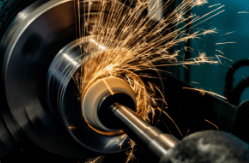

Grinding

Grinding metal plates can achieve precise dimensions, tight tolerances, and a smooth surface finish that is not obtainable through other machining techniques. Depending on the needs of your application, this process is performed for various purposes, such as:

- Achieving Accurate Dimensions. By removing small amounts of material, grinding can achieve exact dimensions and tight tolerances. This is key in ensuring that the plate meets specific design or engineering requirements.

- Creating a Smooth Surface Finish. Grinding can be used to provide a high-quality surface finish by reducing roughness and imperfections that can result from other machining methods.

- Creating a Flat Surface. The grinding process can correct warping and other irregularities in the plate, ensuring a flat, uniform surface. This is critical for applications requiring precise contact and alignment.

- Removing Material. Grinding provides an effective way to remove small amounts of material to finetune the shape and size of metal plates, especially for harder materials that are challenging to machine using other methods.

Overall, grinding services are a great way to achieve the final dimensions and quality needed for high-precision applications.

Heat Treating

Heat treating is a technique used to enhance a metal’s characteristics and mechanical properties, such as strength, hardness, and resistance to wear and deformation. This is often required to meet specific demands for various engineering and manufacturing applications. We can heat treat all of our product lines, including titanium, nickel, aluminum, stainless steel, carbon steel, alloy steel, copper, brass, and bronze. Our heat treating process follows these main steps:

- Solution Heat Treatment. The process begins by heating the metal to a high temperature (approximately 900 °F-1000 °F or 480 °C to 540 °C), causing the alloying elements to dissolve into a solid solution. The material is then quickly cooled, typically by quenching in water, to keep the dissolved elements in a supersaturated state.

- Aging (Precipitation Hardening). After solution heat treatment, the metal undergoes aging to allow the alloying elements to precipitate out of the solid solution. This can be performed at room temperature (natural aging) or elevated temperatures (artificial aging) to improve the hardness and strength of the material. Aging times and temperatures vary depending on the specific alloy and desired temper.

Continental Steel’s heat treating services can be used to achieve numerous types of tempers. Ask us about the following:

- O

- H14

- H116

- H32

- H34

- H321

- T3

- T31

- T3511

- T4

- T5

- T6

- T6511

- T73

- T7451

- T81

- T851

- T8511

Aluminum tempers are chosen based on the starting material and the properties you want to end up with. Copper and bronze grades can be provided in Soft Annealed (H00), ¼ hard (H02), ½ hard (H04), or full hard (H08). We also supply some specialty tempers of stainless steel, including H1150, H900.

Offset Drilling

Offset drilling services can meet the needs of various applications, ranging from aerospace engineering to automotive manufacturing. Offset drills are known for their angled chucks, allowing them to drill in awkward or tight spaces where conventional drills can’t fit. Offset drilling capabilities offer the following benefits:

- Precision

- Accessibility to Challenging Spaces

- Ability to Maintain High Quality Standards (even in demanding conditions)

BTA High-Speed Drilling

BTA high-speed drilling is a deep hole drilling process that uses a specialized drilling tool attached to a cylindrical drill tube to produce deep holes in metal workpieces. BTA drilling capabilities offer a highly effective way to bore your material while maintaining high precision and accuracy. This method is cleaner and more reliable than traditional twist drills, and can achieve higher feed rates and larger diameters than gun drilling.

Boring

Continental Steel can offer boring services for customers across diverse industries. This highly precise and versatile process is used to enlarge or improve a hole that has already been cast or drilled. It utilizes a single-point cutting tool or a boring head consisting of several cutting tools to enlarge a hole and enhance its surface finish and concentricity. Boring is commonly chosen for applications with specific hole size and finish requirements.

Honing

Honing capabilities can remove small amounts of metal from the inside surface of holes, bores, pipe, and tubes. This process is typically performed as a final fine-tuning step and uses a rotating abrasive stone to remove about 0.005 mm of thickness from the desired area.

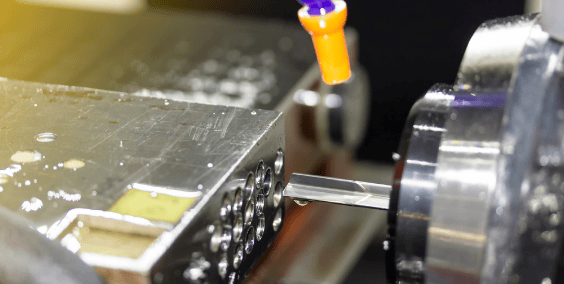

Lathe Work

A lathe is a type of specialized machining tool used for shaping metal workpieces. The lathe machines work by spinning the workpiece in a chuck while a stationary cutting tool removes unwanted material to create the desired shape. This process is commonly used to create cylindrical components with internal and external features, such as tapers, slots, and threads.

Anodizing

We can have anodizing services done to finish parts made from aluminum and other metals. Anodizing is an electrochemical process that coats a metal component with an oxide surface layer, resulting in improved durability and an attractive finish. It helps parts resist wear and corrosion, and ensures they maintain cosmetic appearance under harsh conditions.

Forging Services

At Continental Steel & Tube, we not only supply our customers with an industry-leading selection of stocked metals, but we also work with specialized metal forgers to meet your specific needs.

Metal forging is a time-tested process and is especially important when creating metal parts requiring the highest levels of strength, consistency, and durability.

If you need a special size or grade that is not in stock, we can work to provide a forging option that will supply you with material that meets your job and time frame requirements. This can eliminate the need for large quantities and long lead times associated with mill production.

Many industries rely on metal forging, including:

- Aerospace

- Military/Defense

- Construction

- Mining

- Automotive

If the metals you purchase from Continental Steel require quality metal forging, there are some great advantages to sourcing your forging services from us:

- Our forging services will meet or exceed the highest industry standards, with the ability to forge a wide range of metals including alloy steel, aluminum, carbon steel, copper, nickel, titanium, and stainless steel.

- We can handle all requests for shapes and sizes including seamless rolled ring, open die forgings, flanges, fittings, bars, blocks, discs, shafts, and many other custom shapes.

- With decades of experience, our staff is extremely knowledgeable in a wide variety of industries including aerospace, construction, marine, mining, oil & gas, and more.

No matter what kind of forging you need, Continental Steel & Tube will work on the best solution for your project.

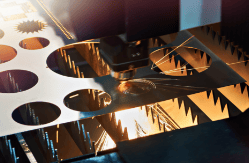

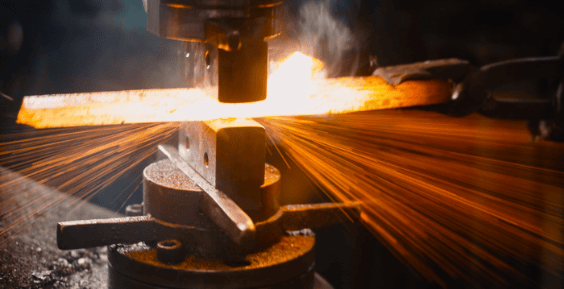

Specialty Metal Cutting

Continental Steel & Tube can provide water jet cutting, high-definition plasma cutting, laser cutting, oxy-fuel cutting, saw cutting, shearing, burning, and more. We hold tight tolerances which depend on the cutting method used (some methods are more naturally more precise than others). Please let us know the tolerances you need for your job and we will do our best to accommodate.

If your project has special metal cutting needs, please let us know. Additionally, if your job requires cutting without heat to retain material properties, please let us know so we can work with you to provide water jet or saw cutting options. For customers requiring precision cutting and special cut tolerances, we will work to find a solution for you.

Industrial Metal Processing

Our industrial metal processing capabilities include:

- Slitting

- Leveling and Tension Leveling

- Annealing

- Turning & Polishing

- Painting

- Chem Milling

- Grinding

- Heat Treating

- Honing

- Galvanizing

- Centerless Grinding

- Production Shearing

- Coil Leveling

Exporting Services

We have years of experience in exporting metal products. This includes work with freight forwarders and export compliance officers. Wherever you are in the world, we can arrange to have the material delivered to the port of your choice or provide a door-to-door service.

In some special export cases, additional steps are required to take the products out of the country, and can sometimes require an ECCN license. Continental Steel & Tube can help navigate this often difficult and challenging process.

Additionally, we supply industry-standard export packing services to protect your materials during transit. We offer specialty packing for ocean freight or air freight, providing the protection needed for your mode of transport. Continental Steel also supplies special shrink wrap, foam, and water-resistant coverings to place inside export boxes.

A Trusted Partner for Your Metal Supply & Processing Needs

Continental Steel & Tube is your one-stop shop. Since 1985, we’ve been a highly regarded specialty metal supplier who not only leads the industry, but also prioritizes customer satisfaction and cares deeply about the relationships we build. We’re sought after for our quality, wide variety of capabilities, and our great technical staff.

We’re also an ISO 9001:2015 and AS9120B:2016 certified company with strategically located distribution centers across the United States. Our distribution points in Florida, Texas, Ohio, and California enable us to get you material quickly and minimize freight costs.

Contact us today to ask about our capabilities or request a quote to get started.