Nickel & High Temp Alloys

Nickel alloys are metals made from combining nickel as the primary element with another material. It merges two materials to deliver more desirable features, such as higher strength or corrosion-resistance. Because of its unique properties, it’s used in a variety of equipment spanning multiple industries.

Continental Steel and Tube are specialty suppliers in all grades and forms of Nickel.

NICKEL ALLOYS (20, 155, 200, 201, 255, 400, 405, 600, 601, 617, 625, 718, X750, 800H, 825, 925, C22, C276, INVAR 36 and more)

Common forms include

TUBE, PLATE, SHEET, PLATE, ROUND BAR, WIRE, FITTINGS and more

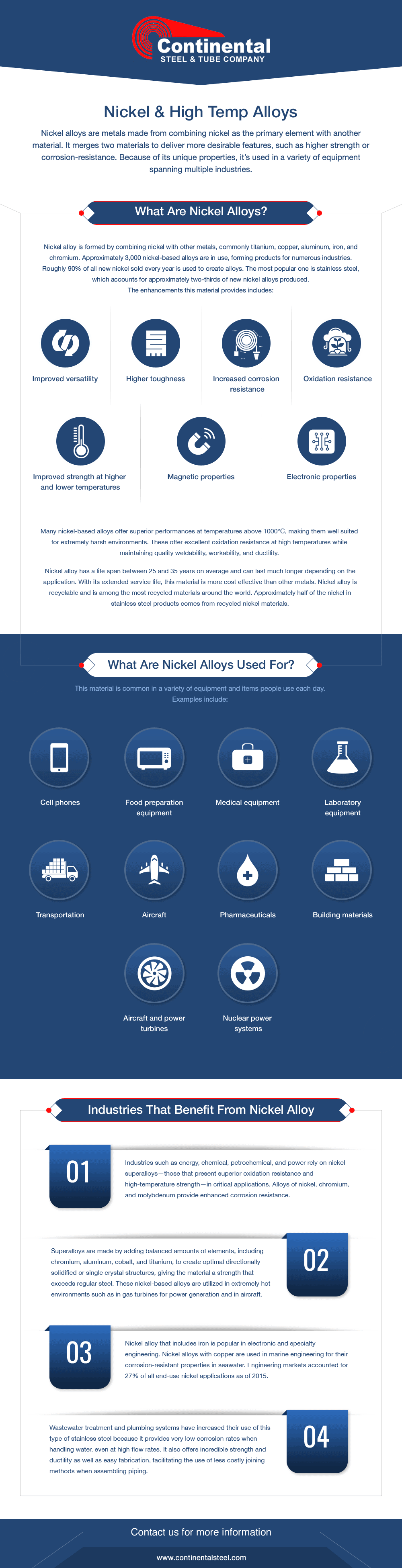

What Are Nickel Alloys?

Nickel alloy is formed by combining nickel with other metals, commonly titanium, copper, aluminum, iron, and chromium. Approximately 3,000 nickel-based alloys are in use, forming products for numerous industries. Roughly 90% of all new nickel sold every year is used to create alloys. The most popular one is stainless steel, which accounts for approximately two-thirds of new nickel alloys produced.

The enhancements this material provides includes:

- Improved versatility

- Higher toughness

- Increased corrosion resistance

- Oxidation resistance

- Improved strength at higher and lower temperatures

- Magnetic properties

- Electronic properties

Many nickel-based alloys offer superior performances at temperatures above 1000°C, making them well suited for extremely harsh environments. These offer excellent oxidation resistance at high temperatures while maintaining quality weldability, workability, and ductility.

Nickel alloy has a life span between 25 and 35 years on average and can last much longer depending on the application. With its extended service life, this material is more cost effective than other metals. Nickel alloy is recyclable and is among the most recycled materials around the world. Approximately half of the nickel in stainless steel products comes from recycled nickel materials.

What Are Nickel Alloys Used For?

This material is common in a variety of equipment and items people use each day. Examples include:

- Cell phones

- Food preparation equipment

- Medical equipment

- Laboratory equipment

- Transportation

- Aircraft

- Pharmaceuticals

- Building materials

- Aircraft and power turbines

- Nuclear power systems

Industries That Benefit From Nickel Alloy

Industries such as energy, chemical, petrochemical, and power rely on nickel superalloys—those that present superior oxidation resistance and high-temperature strength—in critical applications. Alloys of nickel, chromium, and molybdenum provide enhanced corrosion resistance.

Superalloys are made by adding balanced amounts of elements, including chromium, aluminum, cobalt, and titanium, to create optimal directionally solidified or single crystal structures, giving the material a strength that exceeds regular steel. These nickel-based alloys are utilized in extremely hot environments such as in gas turbines for power generation and in aircraft.

Nickel alloy that includes iron is popular in electronic and specialty engineering. Nickel alloys with copper are used in marine engineering for their corrosion-resistant properties in seawater. Engineering markets accounted for 27% of all end-use nickel applications as of 2015.

Wastewater treatment and plumbing systems have increased their use of this type of stainless steel because it provides very low corrosion rates when handling water, even at high flow rates. It also offers incredible strength and ductility as well as easy fabrication, facilitating the use of less costly joining methods when assembling piping.

Find a Solution for Your Needs

Nickel alloy offers excellent advantages over other metals in numerous applications. Strength and resistance make it well-suited for everyday uses in critical harsh environments. For more information about Continental Steel’s nickel alloy products, request a quote today.